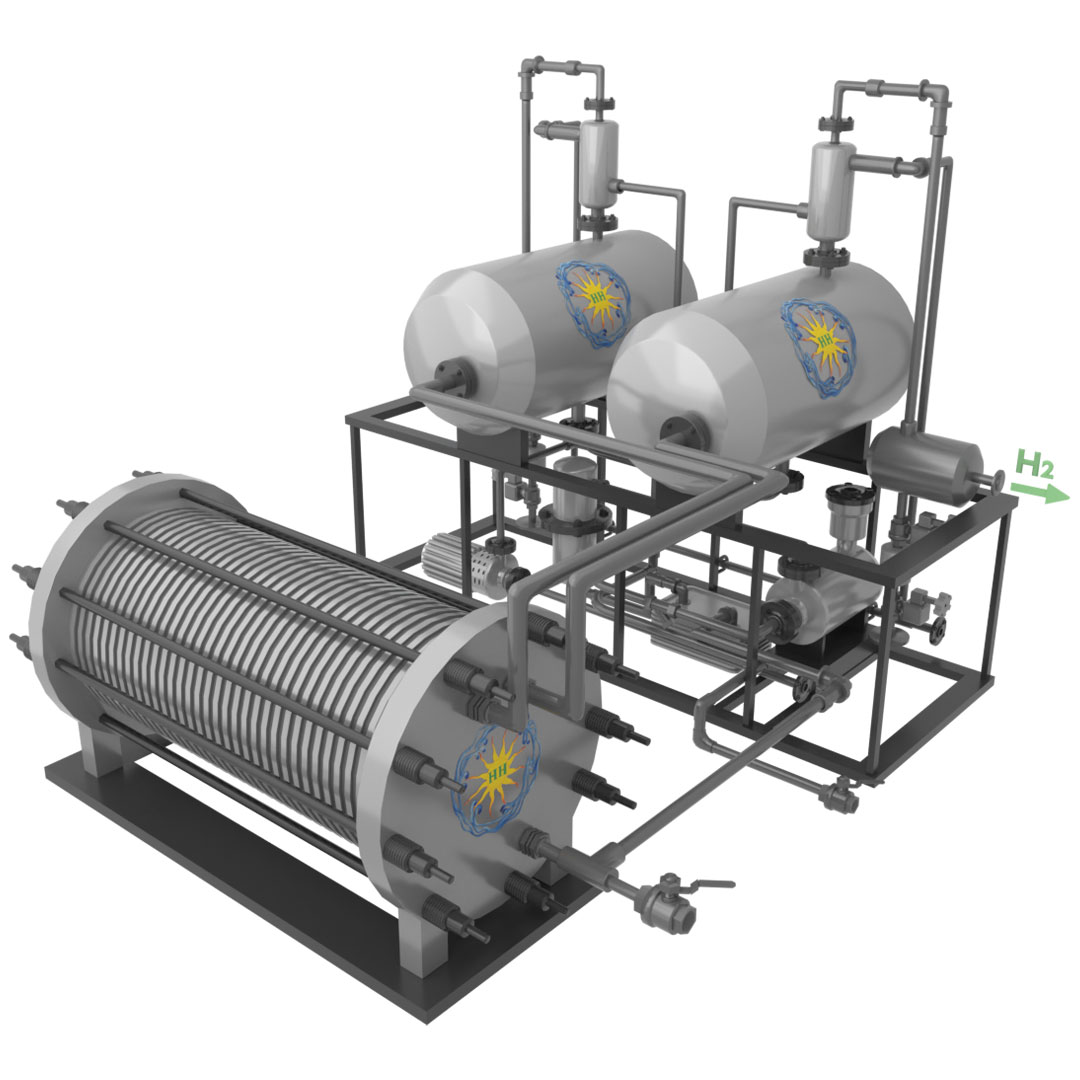

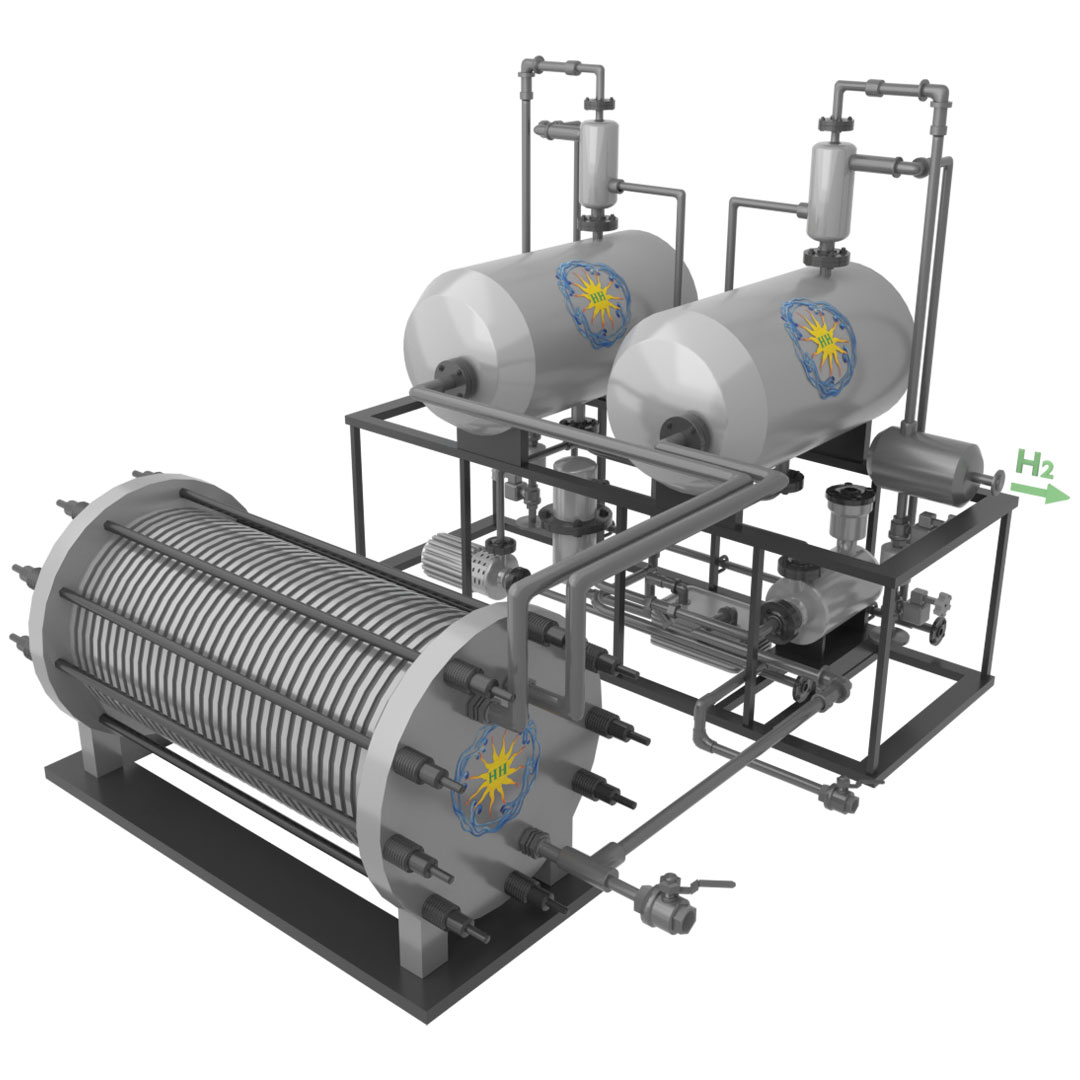

Humble Hydrogen (HH) High Pressure Alkaline electrolysers, the HYPALE Series features a hydrogen gas production from as low power as 30kW to up to 4 MW per stack. The HYPALE 4MW single stack system can produce up to 800 Nm3/h of hydrogen or just over 1.7 ton per day.

To support the worldwide trend for large scale hydrogen production, Humble hydrogen has devised a novel stack modular concept supporting customer’s customized hydrogen plant sizing. Different configurations, applications, and size are available on request.

Humble Hydrogen supports the design, manufacture, deployment, installation, commissioning and after sale support for all the HYPALE Series. Containerised solutions in 20-foot and 40-foot are available ensuring all safety and ancillaries are installed as a package. Any containerised package provided by Humble Hydrogen will dramatically reduce the time for installation and commissioning at customer site.

The HYPALE is an ideal cost-effective electrolyser solution for producing reliable, clean, and green hydrogen. Both the oxygen and hydrogen gas separators are designed to the highest standards, both attached to an appropriate customed built cooling system.

A highly advanced pump allows the recirculation of the lye, which is also attached to a cooling system. The lye cooling circuit is also used to maintain the electrolyser stack at the best operating temperature.